Retrofitting a sprayer from fixed to variable dosage is the most effective way to ensure real savings on pesticides, while also ensuring that the treatment is proportionate to the canopy volume.

Click here to download the brochure

This kit, developed in collaboration with the Agricultural Engineering research group of the Department of Agricultural, Forestry and Food Sciences (DiSAFA) at the University of Turin, is intended for use with existing vineyard and orchard sprayers.

The kit consists of a dual-technology sensor to be installed at the front of the tractor, a control unit and a series of solenoid valves activating the individual nozzles.

The amount of spray output is regulated by electronically varying the opening and closing times, which alternate every tenth of a second, thanks to the PWM system..

The PWM system operates at a fixed pressure, which can be adjusted to obtain the desired droplet size from the nozzles, ensuring the best possible effectiveness of the dispensed product.

These components ensure that each nozzle is automatically turned off in the absence of vegetation and automatically dispenses a quantity of spray proportional to the volume of canopy detected by the front vegetation sensor in its presence.

This kit can be applied to most existing sprayers by simply modifying the nozzle dispensing system. Nozzles have also been successfully applied to pneumatic machines at the air diffusers.

The retrofit can also include, upon request:

– a set of flanges with different internal diameters to limit air suction,

– two electric actuators to move the fins that automatically direct the spray flow onto the apex of the canopy, limiting off-target dispersion.

This retrofit solution can give new life to sprayers that are still efficient without having to replace them with new machines.

According to measurements taken by the University of Turin, efficiency in terms of product dispensed on the foliage is increased by 100%. With an expected average saving of 50% on pesticides, the investment is expected to pay for itself in three to four years for a 10 hectare area.

The improved dispensing, the reduction of the environmental impact and the consequent protection of the ecosystem and human health would naturally be enormously beneficial from a technical, social and environmental standpoint..

Photo gallery

Demo Video

|

|

|

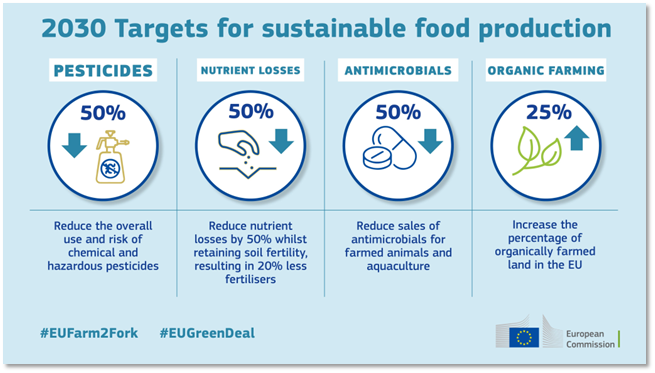

Our kit aligns with the direction indicated by the EU for the 2030 Agenda on the sustainability of food production.