|

“Technical Innovation” Award at EIMA (International Agricultural Machinery Exhibition) in Bologna, Italy |

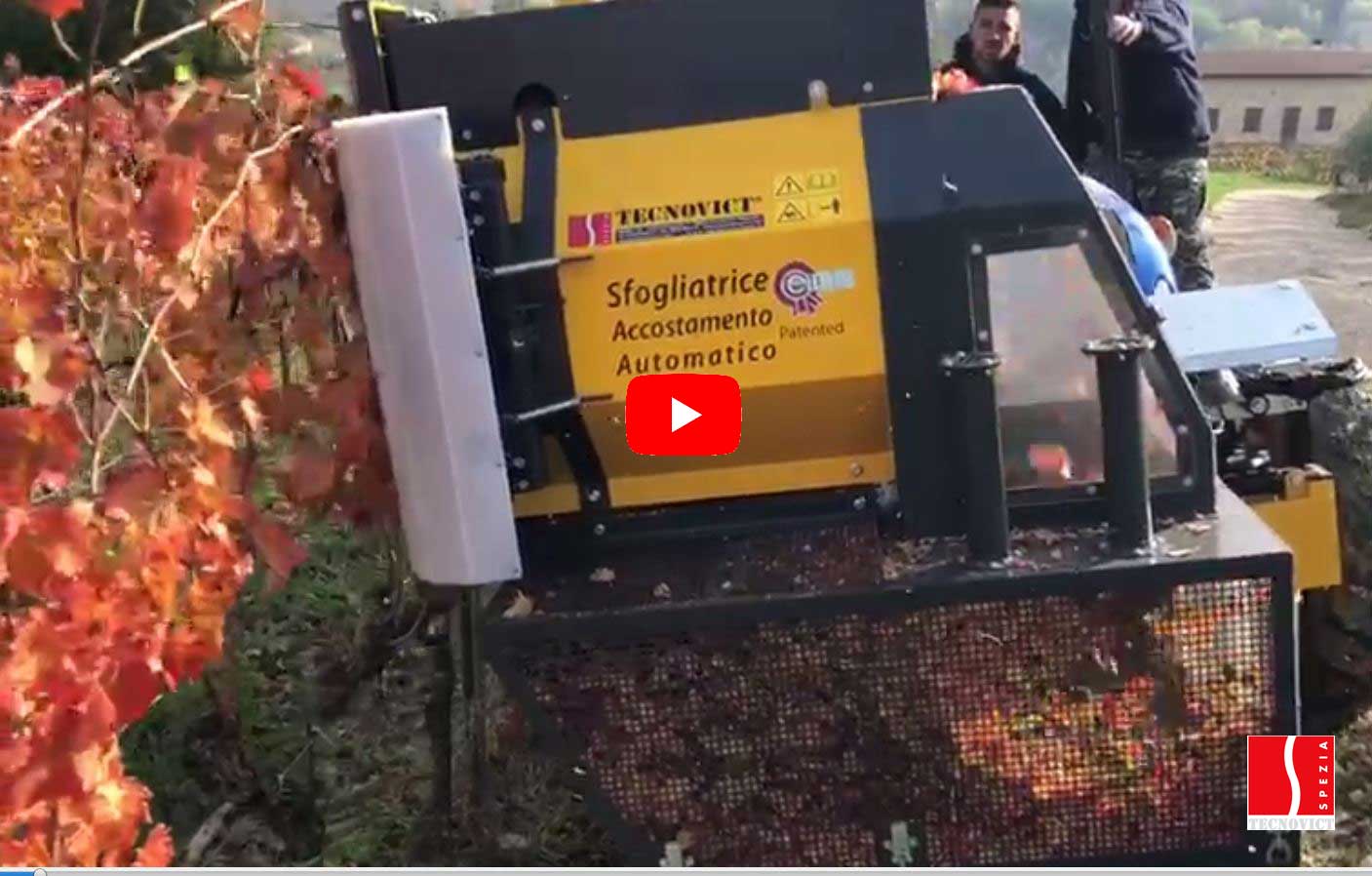

- At the most important contest of technical innovations for agriculture held in Italy, the manufacturer TECNOVICT, based in Pianello Val Tidone (Piacenza), was awarded a prize (its seventh!) for its machine designed to pick and store grapevine leaves – then sold as a by-product to the cosmetics and pharmaceutical industry.

- Special compounds that can be obtained from by-products of the wine industry have become increasingly popular in recent years. There has been a greater focus on research for a more efficient use of these by-products. Various bioactive compounds can be found in spent grape marc and grape seeds. More generally, the value of wine waste can be enhanced by following different strategies, thanks to its chemical characteristics and the presence of a large variety of high added value compounds.

Among the most interesting active ingredients are anthocyanidins; these give wine its colour, astringency, bitterness and partly taste, too. Phenols also play an important role during wine aging. Anthocyanidins are the only cationic group among flavonoids; this makes them unique for their chemical characteristics.

-

Anthocyanin is in fact anthocyanidin bound to a sugar. We always refer to anthocyanins and not anthocyanidins, because these are the molecules found in wine. Anthocyanins are known to be responsible for the wide range of colours (from red to yellow) of flowers, fruits and leaves.

If the extraction of anthocyanins from biomass resulting from wine making would be theoretically possible, in actual fact, these substances would have been degraded by the alcoholic fermentation process they have gone through. Consequently, pure anthocyanins are more effectively extractable from vitis vinifera leaves, especially when their concentration is at its peak, at the end of their production cycle, immediately after the grape harvest.

Final consideration

- Tecnovict was the first in the world to manufacture equipment for picking and recovering grapevine leaves. Financially, this has a huge impact as up to 10 tonnes, the machine manages to reduce harvesting costs by over 50% and its use would already be cost-efficient from about 4 tonnes upwards.

Probably the most efficient leaf picking technique would be to use the machine for removing the outer leaves and human resources to remove the inner ones.

This design is yet more proof that agriculture can find new outlets in unexpected applications: in this case, grape leaves picked after grape harvest for use in the pharmaceutical and cosmetics industry as a high-value by-product of one of our most noble and ancient crops.

Another major achievement for a small-sized company that has turned its focus on research and innovation into a success story – winning this coveted prize for the seventh time, and the sixth in a row: a truly record-breaking result.